Low Location Lighting Measurements | ||||||

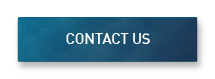

Low Location Lighting (LLL) plays a vital role in ensuring maritime safety, providing occupants with clear guidance and visibility during emergencies and evacuation procedures onboard vessels. As a leading provider of photoluminescent safety signage solutions in the maritime industry, Everlux Maritime has the experience and the approval as Service Supplier by DNV for providing Low Location Lighting solutions and Measurement services that comply with regulatory standards. If you would like to know more about Everlux Low Location Lighting Measurement service, please contact us.Why Are Low Location Lighting (LLL) Measurements Necessary?According to SOLAS 2004, Low Location Lighting (LLL) systems must be installed on all passenger ships carrying more than 36 passengers, with the objective of clearly identifying the routes of escape in the case of an emergency situation. According to the IMO Resolution A.752 (18), Low Location Lighting systems should be visually examined and checked once a week by the crew and a record should be kept. Additionally, at least once every 5 years, all Low Location Lighting must have its luminance measured by an Approved Service Supplier. The inspection and measurement of Low Location Lighting systems is a mandatory requirement, in order to verify the compliance of these safety signs with international regulations and ensure that luminance levels meet the required standards and remain visible under emergency conditions.

How Does a Low Location Lighting Measurement Work?

During a Low Location Lighting measurement, the luminance or light output of the LLL system is assessed. The primary goal of a Low Location Lighting measurement is to verify that the lighting output of the LLL system meets the required standards for visibility and effectiveness. It ensures that the safety signs remain clearly visible and legible during emergency situations, such as power outages or low light conditions. Electric or Photoluminescent Low Location Lighting systemThe measurement approach may vary depending on the type of Low Location Lighting system being assessed.

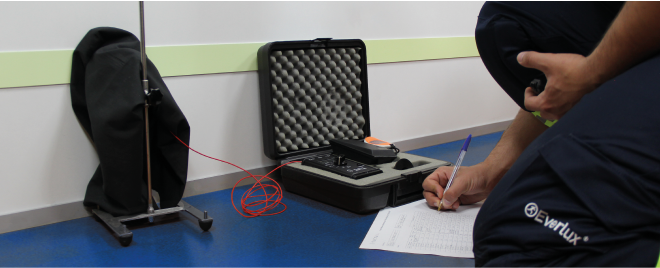

LLL Measurement Equipment Accurate measurement of lighting output requires the use of specialized and certified equipment, such as a non-contact luminance meter. This equipment is specifically designed for Low Location Lighting measurements, ensuring precise and reliable readings. It guarantees that the measurements accurately reflect the lighting capabilities of the LLL system. LLL Measurement PointsA predetermined set of measurement points must be established, covering critical areas where the Low Location Lighting system is installed. These points are strategically selected to represent various spaces and pathways within the vessel.Here are some commonly identified measurement points:

The measurement equipment is used to capture luminance values at each measurement point, ensuring accurate and reliable data collection. This information forms the basis for assessing compliance and identifying areas that require improvement. LLL Analysis and Reporting:Upon completion of the Low Location Lighting measurement survey, the collected data is analyzed and compared with regulatory standards and requirements. A report must be delivered, highlighting compliance status, areas of concern, and recommended actions to enhance safety signage effectiveness. The report encompasses all the readings obtained during the measurement process. If upgrades or modifications are necessary to meet regulatory standards, they are clearly outlined in the report. This document serves as a valuable guide for Ship owners, providing actionable insights to maintain or enhance the effectiveness of their Low Location Lighting systems and create a safe environment for passengers and crew members during critical situations. In certain cases, the Low Location Lighting (LLL) system does not meet the necessary specifications. When this occurs, the replacement or upgrade of the inadequate Low Location Lighting system is essential to ensure compliance with regulations. Everlux has extensive knowledge in the installation and renewal of LLL systems for a wide range of vessels. With our expertise and dedication, we ensure that your Low Location Lighting system is brought up to the required standards, guaranteeing the safety of your vessel and its occupants. Why choosing Everulx for LLL measurements?

As an Approved Service Supplier by DNV for Low Location Lighting Systems Measurements, Everlux ensures the best practices and compliance with all the applicable regulations, through an experienced and qualified team. If you are currently working on a newbuild or refurbishment project, Everlux experience can be a valuable help.

|

-

PRODUCTS

- Means of Escape Signs (MES)

- Emergency Equipment Signs (EES)

- Other Safe Condition Signs

- Life-Saving Appliance Signs (LSS) - IMO Signs/ Marine Safety Signs

- Fire-fighting Equipment Signs (FES)

- Signs for Elevators and Lifts

- Fire Control Plan Signs For Shipboard Use (SIS)

- Damage Control Plan Signs

- Low Location Lighting (LLL) System

- Panoramic Signs

- Marking Strips

- Prohibition Signs (PSS)

- Hazard Warning Signs (WSS)

- Mandatory Action Signs (MSS)

- Multipurpose Combination Signs

- Information Signs

- ISPS Code Signs

- Infection Prevention and Control Safety Signs

- Safety Signs for Super Yachts

- Offshore Wind - Safety Signs

- Water Safety Signs

- Temporary Tie Tags

- SOLAS TAPE

- Pipe Content Identification Tapes

- Anti-Splashing Tape

- IMDG Code

- Safety Awareness and Training Procedures

- General Safety Awareness Notices

- Escape Plan Signs | Mimic Signs

- Fire Control and Safety Plans

- Everlux Frames

- Everlux Adhesive

- SERVICE

- BECOME A DISTRIBUTOR

- TECHNICAL INFORMATION